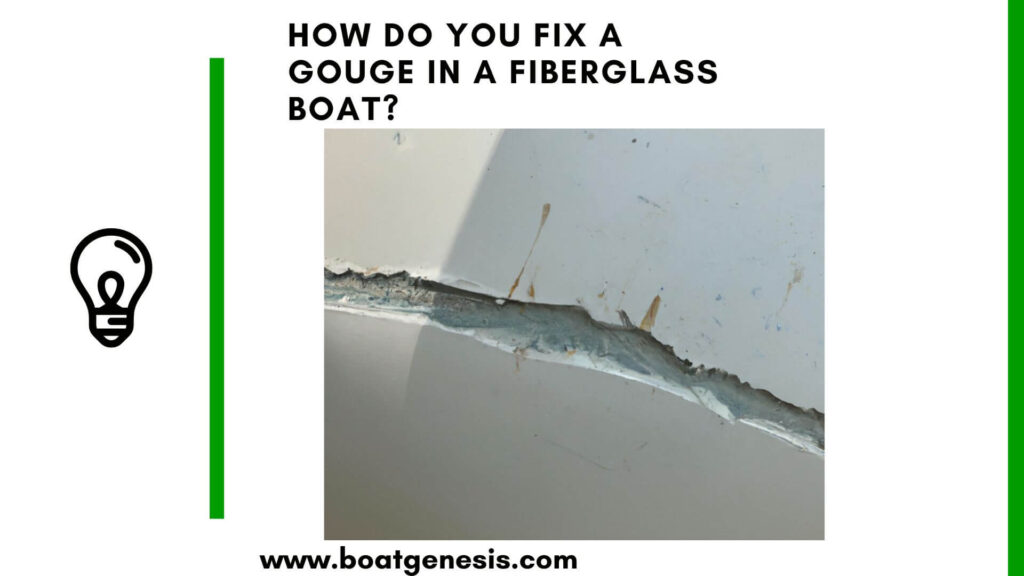

If your fiberglass boat gets a gouge, it can leak and cause water damage if not repaired. The good news is that fixing a gouge is a straightforward process.

Follow the steps outlined below.

How do you Fix a Gouge in a Fiberglass Boat?

- Clean, dry and sand the area around the gouge with 80-grit sandpaper to rough up the surface. This helps the repair material adhere properly.

- Stop any leaking by forcing quick-set epoxy paste into the hole. Smooth the taper once it stops leaking and allow it to fully cure.

- Cut fiberglass cloth to overlap the damaged area by at least 2 inches on all sides. Saturate cloth layers with selected resin like polyester or epoxy.

- Apply 3-5 saturated cloth layers over the hole, allowing each layer to partially cure before adding the next one.

- Once built-up fiberglass has hardened, use body filler putty to smooth and blend the repair area. Match surrounding gelcoat finish.

- Sand and polish repair to an invisible finish. Apply wax to restore UV protection.

Repairing Deep Gouges

If a gouge fully penetrates the hull and creates a large hole bigger than a few square inches, structural rebuilding gets more intensive.

You may need to create an internal support structure before applying fiberglass layers.

Cut plywood or plastic sheets to overlap the inner hole surface by at least 4 inches around the edges. Coat wood in epoxy to waterproof it before fastening it in place with thickened epoxy adhesive, screws or mechanical fasteners. Creates backing to apply fiberglass against.

Alternatively, cut fiberglass into strips, saturate it with resin and lattice it within a hole to create a reinforcement skeleton.

Follow the normal process of filling the hole with quick-set epoxy, then apply 4-6 layers of 10 oz or heavier fiberglass cloth. Allow extensive curing time before fairing and finishing. Thorough drying and curing prevents future cracking or delamination.

Deeper structural repairs may require pulling the boat out of the water for access. Consult professionals if unsure about the full scope of damage.

Extensive gouges increase vulnerability to leaks if not addressed properly.

What Causes Gouges in a Fiberglass Boat Hull?

There are a few common causes of gashes or holes appearing in the fiberglass skin of a boat hull:

- Striking submerged objects like rocks, sandbars, reefs, discarded metal objects, etc. This can happen while boating, docking, trailering or beaching the boat.

- Impact damage from boat trailers, especially if the bunks are not properly padded and adjusted. The constant rubbing of the fiberglass bottom against exposed metal can wear holes over time.

- Cracks from leaving the boat exposed to freezing temperatures while storing it over winter. Trapped bilge water expands as it freezes and fractures the hull.

- Poor quality repairs cracking or flaking out after time. If previous damage is not properly repaired, flaws can lead to new holes or gouges.

- General wear and tear to the gel coat surface make the underlying fiberglass vulnerable. Gelcoat becomes less flexible as it ages.

Inspecting and maintaining your boat regularly allows you to address any flaws in the surface before they penetrate deeper into the hull laminate structure.

Pay special attention to areas around the keel, bow and strakes when checking for surface issues.

Difference Between Gouges and Holes

Some people tend to confuse gouges and holes. But it’s important to know the difference so you know how to identify and fix each.

While there can be some similarities, gouges and holes each have distinct qualities:

Gouges:

- Long scratches or abrasions in gelcoat that penetrate fiberglass layer beneath

- Caused by scraping against rocks, grinding, etc. (more surface layer issues)

- Results in weak spots and potential leakage issues in hull

- Requires restoring missing fiberglass via layered cloth application

Holes:

- Punctures or voids that go fully through outer and inner boat layers

- Usually caused by direct impacts from force-piercing object (anchor, forklift, crash, etc.)

- Immediate leakage concern

- Plugging and sealing layers priority before fiberglass build up

So in short:

Gouges are scars, scratches and divots in gelcoat and below.

Holes are punctures completely through the hull.

The key is to accurately identify the type of damage and then carry out the appropriate corresponding repairs.

FAQ About Fixing Gouges

Gouges in fiberglass boats can be caused by various factors, including collisions with objects in the water, scraping against docks, impact with debris, or accidental mishandling.

Inspect the gouge carefully. If it’s a small surface scratch or minor gouge without any structural damage, it might only need cosmetic repair. However, if the gouge is deep, exposes fiberglass layers, or affects the boat’s structural integrity, it will require more extensive repair.

Yes, minor gouges and scratches can often be repaired by DIY methods using fiberglass repair kits available at marine supply stores. These kits typically include resin, hardener, fiberglass cloth, sandpaper, and instructions for repairing minor damage.

Larger or more severe gouges might require professional assistance. Structural damage or deep gouges could compromise the boat’s integrity if not repaired properly. Consult with a professional boat repair technician or a marine expert for such repairs.

The time required depends on the size and severity of the gouge, as well as the repair method used. Minor repairs might take a few hours to a day, while more extensive repairs could take several days to complete.

It’s advisable to allow sufficient time for the repair to cure completely before using the boat. Follow the instructions on the repair kit or seek guidance from a professional to determine the appropriate curing time before returning the boat to the water.

Practice careful navigation, avoid collisions with objects, maintain a safe distance from docks and other boats, and regularly inspect and maintain your boat’s hull to prevent gouges and scratches. Using fenders and boat covers when mooring can also help protect the hull.

And there you have it – a streamlined, easy guide on patching fiberglass boat gouges so you can get back on the water.

Let me know if you have any questions!