Sanding a fiberglass boat is crucial in restoring the surface and ensuring strong paint or gelcoat adhesion.

Whether you’re prepping for refinishing, fixing oxidation, or repairing small imperfections, sanding the hull properly makes all the difference in the outcome.

In this guide, we’ll break down every step you need to know—from grit selection to wet sanding techniques—so you can get a smooth, professional-grade finish that lasts.

KEY TAKEAWAYS

- Proper sanding is essential for paint adhesion, gelcoat repairs, and a smooth final finish.

- Start with coarse grits (80–100) for oxidation or damage, and work up to finer grits (220+).

- Use aluminum oxide or silicon carbide sandpaper—they’re best suited for fiberglass surfaces.

- Wet sanding is ideal for a flawless, glossy finish while reducing airborne dust.

- Use light, consistent pressure to avoid swirl marks or sanding through the gelcoat.

- Always clean the surface thoroughly between sanding stages to remove dust and debris.

- Inspect the surface often for high/low spots, scratches, and imperfections before moving to the next grit.

Steps for Sanding a Fiberglass Boat Gel Coat

1. Assessing the Surface

Before sanding, thoroughly clean the fiberglass and allow it to fully dry. Carefully inspect for any flaws, gouges, or uneven areas.

Determine the smoothness required for your project finish. Identify which grit sandpaper is needed to remedy imperfections while achieving the necessary smoothness.

2. Selecting Sandpaper

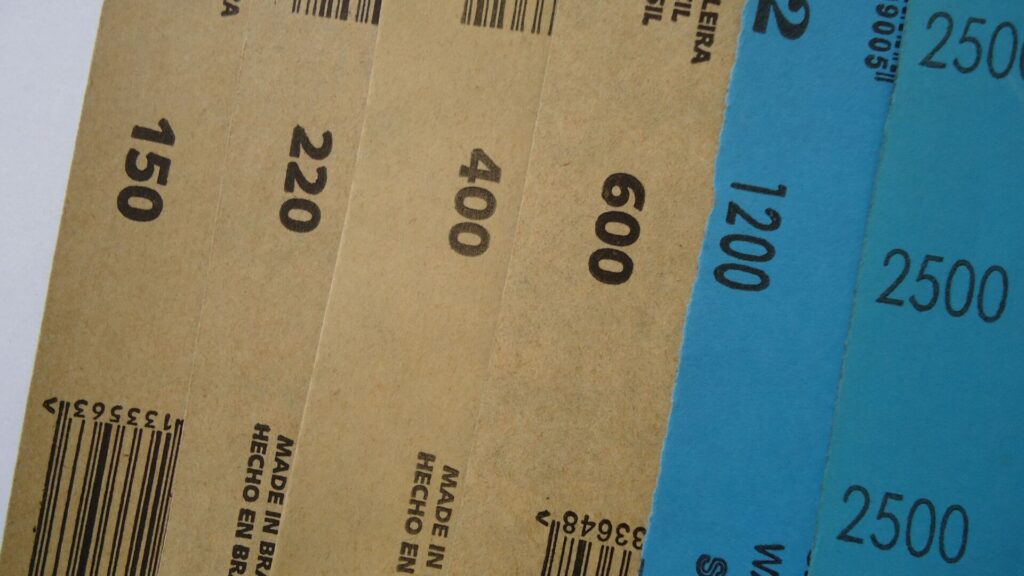

For fiberglass sanding, aluminium oxide and silicon carbide papers are best. The commonly used grit sizes are 80, 100, and 120.

Start with more coarse 80 or 100 grit to remove heavier oxidation or surface defects. Then use progressively finer 120 and 220 grits to smooth the area for finishes and paint adhesion.

Always use high-quality sandpaper that resists clogging.

==>> Read also my recommended best sanding blocks for your fiberglass boat here!

Want to avoid costly fiberglass boat repair mistakes?

Learn how to inspect damage properly, decide when to DIY, and prevent expensive fiberglass problems before they start.

3. Using a Sanding Machine

If you’re working on a large surface area or dealing with heavy oxidation, a random orbital sander or DA (dual action) sander can significantly reduce your workload and improve consistency.

- Choose the right sander: Use a variable-speed random orbital sander for better control and to avoid swirl marks. Keep the RPM below 6,000, especially on gelcoat.

- Use hook-and-loop sanding discs with appropriate grit levels. Stick with marine-grade discs made from aluminum oxide or silicon carbide.

- Keep the sander moving: Never let it sit in one spot. Use slow, even passes and avoid applying too much pressure—let the sander do the work.

- Mind the edges and contours: Switch to hand sanding around tight spots, hardware, and edges to avoid gouging or sanding through the gelcoat.

- Dust control: Connect your sander to a vacuum system if possible, or use a sander with built-in dust collection to keep the work area clean and safe.

Power sanding is efficient, but always finish by hand in tight areas or to blend the final surface for an even finish.

4. Sanding Technique

When sanding gel coat on a fiberglass boat, always use straight, even strokes in a consistent direction. Apply moderate pressure, allowing the abrasive paper to do the work. Over-pressuring causes uneven scratches requiring extra sanding.

Frequently switch stroke direction to ensure level sanding.

If using power tools, use variable speed to control the abrasion rate. Move slowly over the gel coating to avoid excess material removal. Carefully hand sand hardware, logos, stripes, and tight spaces.

5. Process Checkpoints

Frequently stop and wipe clean sanded areas to inspect smoothness and verify all imperfections are removed.

Check for uneven spots requiring additional sanding to prevent visibility under the finish.

Once the entire surface meets smoothness standards, use a tack cloth to remove all dust before progressing to polishing compounds or finishes.

Wet Sanding a Fiberglass Boat

When refinishing a fiberglass boat, wet sanding the exterior gel coat layer is key for a flawless glossy finish.

Wet sanding uses water to provide lubrication during the sanding process to achieve an ultra-smooth surface finish. As grit particles abrade the surface, the water floats away the sanded material keeping scratching to a minimum.

This allows progressively finer grits to be used without causing deeper visible scratches or swirl marks.

The key reasons to wet sand fiberglass gel coat are:

- Create a smooth surface for gloss clarity

- Use finer grit papers more safely

- Reduce scratches and swirl marks

- Eliminate airborne fiberglass dust

- Enable better control through the process

Below are the steps for wet sanding fiberglass boat gel coat.

This guide helps boat owners understand fiberglass damage clearly — what matters, what doesn’t, and when repairs are truly necessary, so small issues don’t turn into expensive mistakes.

See What Every Boat Owner Should Know →Note that the gel coat is only 5-25 mils thick according to Jamestown Distributors, so careful process control is imperative.

Preparing to Wet Sand

Fill cracks or flaws in the gelcoat using recommended repair compounds before sanding. Thoroughly wash the area with a boat soap solution to remove wax, grease and surface contaminants.

Start by dry sanding the gelcoat to remove heavy oxidation and surface defects using 600-800 grit.

Wet Sanding Process

Begin wet sanding by keeping the area wet with clean water while sanding to provide constant lubrication.

Use a foam sanding block to back up your paper to ensure an even scratch pattern.

Start with 1000 grit wet/dry making straight passes until achieving a uniform scratch pattern without visible unevenness or swirl marks.

Wipe frequently and change water often to prevent scratching from built-up residue.

Finishing Steps

Progress through finer grits up to 2000 grit repeating the prior steps until obtaining a smooth, glass-like finish.

Exercise caution to avoid excess pressure or over sanding which can cut through the gelcoat. Complete by thoroughly rinsing and then immediately drying the area.

Carefully inspect under bright light for any remaining imperfections.

FAQ

Here are answers to some frequently asked questions about sanding fiberglass boat hulls:

Random orbital sanders allow good control and minimize swirl marks. Models with variable speeds under 6,000 RPM are ideal for gelcoat.

Yes, wet sanding helps reduce airborne dust. However, don’t let water pool as this can impact results.

Applying too much pressure and not moving evenly can create visible swirls. Ensure you sand methodically using moderate pressure.

routinely stop and wipe away all dust to visually inspect for defined scratch marks. Run your hand over the area as well feeling for defects.

Use extra care when sanding near or below the water line where the gelcoat is thinner and more susceptible to issues with excessive material removal.

Conclusion

Sanding your fiberglass boat is an essential part of keeping it looking great and performing well.

With the right tools, materials, and a careful approach, you can restore faded areas, ensure a smooth surface for painting, and protect your boat for the long run.

Paying attention to each step of the sanding process helps prevent future problems and gives your boat a polished, professional appearance.

So, whether you’re new to boat maintenance or have years of experience, investing the time to sand thoroughly will keep your boat in top shape for all your future outings on the water.

Warren is the founder of BoatGenesis and brings practical experience in fiberglass boat repair, marine equipment testing, and powerboat building. He has worked on a range of repair and restoration projects and now focuses on creating clear, research-based guides to help boat owners avoid costly mistakes and make smarter maintenance decisions. Learn more about Warren.