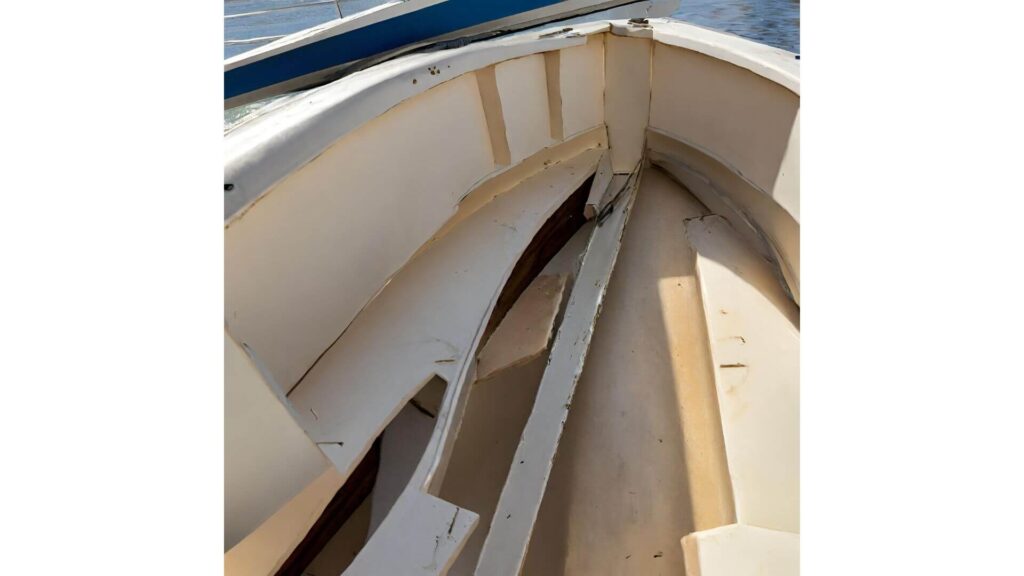

Over time, water can seep into your fiberglass boat’s stringers causing dry rot decay and structural failure. Stringers are critical for providing integral hull support and reinforcements for deck hardware.

Replacing rotten stringers restores strength while stopping ongoing moisture risks. With proper tools and safety precautions, replacing stringers is a doable DIY project for experienced boat owners.

This article guides you step-by-step through the entire fiberglass boat stringer replacement process to save thousands over professional yard repairs.

Fiberglass Boat Stringer Replacement Process Overview

- Remove deck access panels/sole above problem stringer

- Extract the old stringer completely with saws if possible

- Clean bonding surfaces by grinding rough areas

- Test fit then seal and coat replacement stringers

- Bond new stringers using thickened epoxy

- Fully encapsulate new stringers in fiberglass

- Reinstall decking/panels and hardware

- Ventilate bilge space for moisture prevention

What are Stringers and Why Replace Them?

Stringers are long structural framing members running fore to aft inside the hull, commonly made of wood or sometimes aluminium or fiberglass composites.

Want to avoid costly fiberglass boat repair mistakes?

Learn how to inspect damage properly, decide when to DIY, and prevent expensive fiberglass problems before they start.

This guide helps boat owners understand fiberglass damage clearly — what matters, what doesn’t, and when repairs are truly necessary, so small issues don’t turn into expensive mistakes.

See What Every Boat Owner Should Know →If freshwater or saltwater moisture seeps in, stringers eventually rot weakening the entire boat.

Ignoring this leads to accelerated decay plus cracked gelcoat or delaminating deck layers as underlying support fails.

By swapping damaged stringers for new sealed replacements, you return integrity to the hull and stop costly damage cascades.

Warning Signs You Need New Stringers

How do you know if stringers are failing? Warning signs include:

- Spongy soft spots in deck walking areas

- Creaking, and groaning noises when boating

- Visible cracks or leaks near stringers

- Discoloration, dry rotting, damp smells

==>> If interested, you should also read my guide about repairing a soft fiberglass boat floor here.

Catching issues early allows simpler repairs or encapsulations. So, do you think your boat stringer can be fixed instead? Read these fiberglass boat stringer repair tips here.

But if more than 25% of a stringer cross-section crumbles from prodding, or has visibly snapped, then the full replacement becomes the proper long-term fix.

What Supplies You’ll Need for the Job

Stringer surgery takes some investment in equipment and materials. Critical stringer replacement gear includes:

- Safety – goggles, respirators, gloves, first aid

- Power Tools – circular saw, multi-tool oscillating saw, reciprocating saw, angle grinder, power sander

- Hand tools – clamps, putty knives, rollers, brushes

- Supplies – 2 part epoxy resin, fiberglass cloth, thickening agents, fasteners, sealants

- New marine-grade plywood stringers cut to a precise fit

Step-by-Step Stringer Replacement Instructions

Once you assemble the necessary gear and your replacement stringers, follow these key steps:

1. Remove Decking and Electrical

- Clear workspace by removing cushions, panels, insulation and any storage bins in the immediate work vicinity

- Caution when disconnecting wires or plumbing leads, cap pipes and wire ends

- Unbolt and extricate decking panels and sole carefully without damage

- Keep hardware like cleats if reusing, and label parts as necessary

2. Extract Old Stringer

- Support the weight of the hull from below with jack stands before extracting stringers

- Remove using long wood chisels to pry loose if possible

- If stuck fast by frames/encapsulation, cut in manageable sections with a sawzall or angle grinder

3. Clean Bonding Surfaces

- Stringers bond chemically and mechanically to the hull interior during the initial build

- Grind surfaces with coarse 80-grit discs to expose clean fiberglass for re-bonding

- Remove all old wood, fiber residue, gel coat chips, greasy grime

4. Test Fit then Seal New Stringer

- Test fit precut new stringers repeatedly for precision gap-free alignment

- Use a belt sander or rasp to refine fit if needed

- Seal and prime all surface areas especially vulnerable end-grain

5. Bond New Stringer Using Epoxy

- Prepare 2-part slow cure epoxy per manufacturer guidance

- Catalyze required resin volume, thickened with adhesive filler

- Cake both mating surfaces thoroughly

- Hoist stringers into place with help, and clamp snugly to extrude excess epoxy until cured

6. Incapsulate Stringer in Fiberglass

- Build up fiberglass protective shell around all sides of the new stringer

- Wrap the stringer fully with 4-6 alternating layers resin saturated cloth

- Creates stiff, weatherproof moisture barrier and structural reinforcement

7. Reinstall Decking and Hardware

- Inspect the substrate, and ensure clean and sound, free of debris like stray wood or old epoxy

- Bed decking panels using a supportive flexible sealant

- Bolt hardware back down with anti-seize compound to prevent future seizure

8. Maximize Ventilation

- Ventilate enclosed bilge area to port and starboard to foster moisture evaporation

- Consider installing more limber holes along the stringer run if none exist

- Use fans to enhance passive air circulation before reassembling

Let me know in the comment section below if you need any clarification or have questions about this fiberglass boat stringer replacement process!

Take Things Slowly for the Best Results

Battling bilge slime, grinding glass dust, and mixing pots of resin and epoxy isn’t for the faint of heart.

Work slowly and double-check everything. But in the end, tackling major stringer surgery yourself pays satisfaction and saves plenty over yard repairs.

Use these stringer replacement steps to steer your own project smooth sailing!

Warren is the founder of BoatGenesis and brings practical experience in fiberglass boat repair, marine equipment testing, and powerboat building. He has worked on a range of repair and restoration projects and now focuses on creating clear, research-based guides to help boat owners avoid costly mistakes and make smarter maintenance decisions. Learn more about Warren.