Fiberglass boat crack repair is needed when those heartbreaking cracks appear in your boat’s hull or deck.

While finding a crack or gouge can be alarming, don’t panic. Most cracks in a fiberglass hull or deck can be successfully repaired if you use the right techniques and materials.

This article will go over the main types of cracks that can occur and the best way to fix them so you can get back on the water.

What Causes Cracks in Fiberglass Boats?

Fiberglass seems like such a sturdy material when used in boat building, so what causes those frustrating cracks? There are a few main culprits:

Impact Damage: If your boat got bumped into a piling while docking, ran aground in shallow water, or collided with a submerged object like a rock or log while boating, the hard-hit can easily crack or gouge the gelcoat and underlying laminate.

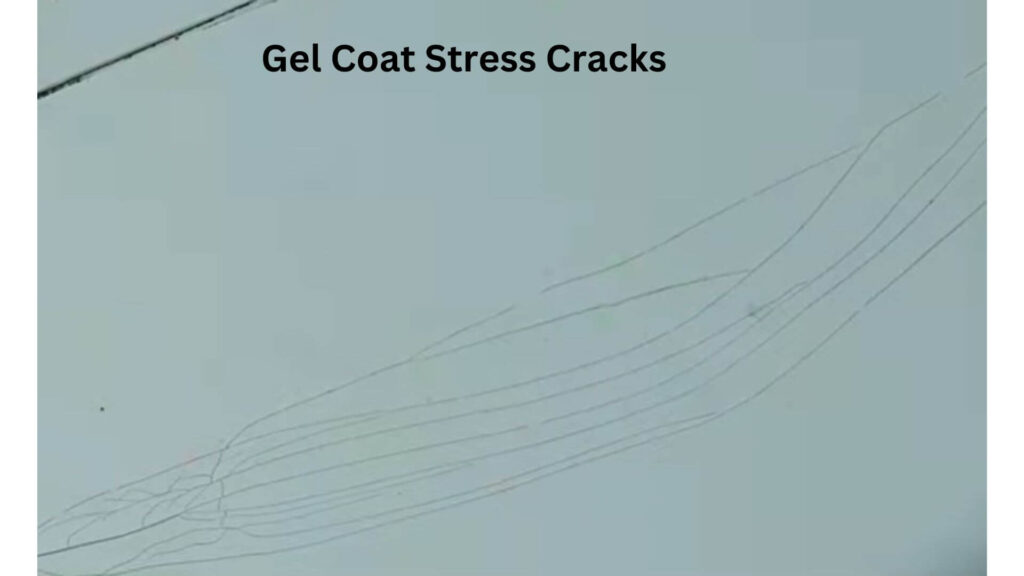

Stress Cracks: Areas around deck hardware, ports, and other protrusions get constantly flexed and can eventually crack under the strain. Lifting slings may crush or crease the hull. Trailers can wear depressions at the bottom. Improper tightening or seismic activity can crack housing mounts over time.

Ageing Issues: As with most materials, fiberglass degrades over decades of sun, weather, and use. The resin holding the glass fibers eventually gets brittle and cracks more easily. Joints between the deck and hull may need resealing to prevent water intrusion issues.

No matter what caused that heart-stopping crack, fixing it correctly is important both for appearance and safety.

The good news is that most cracks—even some that look like a spider web across your hull—can be repaired by a savvy boat owner with patience and the proper products.

Fiberglass Boat Crack Repair Tips

1. Repairing Surface Cracks with Touch-Up Gelcoat

For minor surface cracks limited to the gelcoat layer, the repair is straightforward by using gel coat touch-up putty or wax sticks made for this purpose. But to understand gelcoat cracks, we first have to talk about what gelcoat is.

Gelcoat is the durable, protective outer layer of resin that covers the reinforcement fibers on a fiberglass boat. It promotes water resistance, reflects UV rays, and provides a shiny surface that’s much easier to clean, polish, and paint than the fibrous layer underneath.

When gelcoat cracks, it’s mostly a cosmetic issue. The fibers below are likely still intact holding together the boat’s structure just fine.

Still, allowing water permeation into cracks isn’t ideal since it can lead to further cracking when water freezes and expands. And even hairline cracks rapidly get grimy, making your boat look unkempt.

Luckily, DIY gelcoat crack repairs are simple:

- Use a Dremel or orbital sander to widen cracks into a “V” and sand the inside rough. Wipe away dust with acetone.

- Fill cracks thoroughly with gelcoat putty, over-filling slightly. Putties like Computrac Marine Gelcoat Repair Kit match most standard gelcoat colors well for near invisible repairs.

- Once the putty has cured fully (often 30-90 minutes), sand flush with surrounding gelcoat using wet/dry sandpaper in 100-400 grits.

- Buff until the repaired area matches the original high-gloss finish using a power buffer and polishing compounds. Apply wax to blend shine.

==>> Also check out my recommended Best Gel coat repair kits for boats here.

2. Deep/Structural Cracks: Grind, Fill, & Glass It

What if the crack goes deeper than surface-level gelcoat damage? Thankfully there are fiberglass repair products that can fix even significant cracks in the fibrous layers under the gelcoat.

Products like polyester or Vinylester resin give you all the materials to wet out fiberglass cloth and rebuild cracked areas from the inside out.

For deep cracks, structurally critical cracks, large cracks, or cracks showing whitish fibers, a more intensive repair procedure is wise:

- Use an oscillating multi-tool or die grinder to open cracks into a “V” shape if needed so sides are roughed up for bonding.

- Vacuum or blow out cracks thoroughly since contaminants prevent good adhesion.

- Mix your preferred fiberglass-specific resin per instructions. Epoxies offer more strength while polyesters match most boats’ factory construction.

- Wet out fiberglass cloth strips or mesh with resin and pack into the crack, working air pockets out from center to edges. Allow to partially cure.

- Fill the remaining crack and blend edges with thickened resin, overfilling slightly. Once cured, sand even with surrounding areas.

- Replace damaged gelcoat using gelcoat putty, spray gelcoat, or rolled/brushed coats. Finish as desired.

Voids behind cracks may need additional patches of glass cloth overlaid outside to disperse stresses.

For very large cracks, specialized fiberglass boat repair facilities have vacuum infusion capabilities to guarantee full saturation for maximum strength. But most cracks can be fixed successfully with the V-grind method using the right resin and fabrics.

3. Stress Crack Repairs Around Boat Hardware and appurtenances

As mentioned earlier, parts protruding through your deck and hull see constant flexing that eventually can crack surrounding fiberglass. These “stress cracks” creep outward year after year until suddenly that small hairline fracture becomes a much larger issue.

But stopping stress cracks in their tracks is quite straightforward by essentially putting the cracked area on a fiberglass diet:

- Open crack into a V-shape and sand insides rough for mechanical adhesion.

- Fill the underside of cracks with thickened resin to saturate fibers and prevent water ingress.

- From the outside, lay fiberglass patches extending several inches wider than the crack in all directions. Wet out patches with neat resin.

- Once cured, redrill any fastener holes needed through the reinforced area. Rebed hardware with flexible marine sealant.

This reduces movement across the cracked section by lowering strains from swelling sealant and flexing hardware. It also provides extremely solid backing to resist those forces without transmitting them to already damaged areas around holes.

For cracks radiating from lifting sling compression marks or trailer bunks, a similar process applies:

- V-grind crack ends and sand out inside surface contaminants.

- Fill the underside with thickened resin to lock fibers in place.

- Glass overlapping reinforcement patches outside to bolster the weakened laminate.

- Fair exterior by sealing with high-fill primer, then sand and paint.

- Pad bunk carpet and adjust bunk/sling positions to prevent re-cracking.

By diminishing movement and impact at crack locations, while structurally mending splits with internal/external reinforcement, you can repair stress cracks in the long run.

4. Spider Cracks

One of the most jarring sights is a spider crack – when a fracture spreads out in long, spindly lines across your boat’s gelcoat surface reminiscent of a spider web.

While the webbing may cover a large area, spider cracks are generally superficial gelcoat issues without deeper underlying damage.

Use the V-grind gelcoat repair method to open up the fine crack lines and fill them from underneath with fiberglass putty or resin to mend these cracks. Then sand smooth and buff to restore an attractive finish.

With some effort, even spiderwebs of cracks can be repaired for good.

If you need more tips on Gel Coat repair, you can also read this article by WikiHow.

When to Call In a Professional for Fiberglass Boat Repairs

While many cracks can be fixed successfully with some grinders, resin, fabric reinforcements, and elbow grease, some warrant handing off to a professional:

- Long cracks (over 12”)

- Major impact damage with suspected delamination

- Major cracks or damage affecting structural stringers

- Large holes spanning multiple hull layers

- Areas of many spidering cracks covering several square feet

- Risk of secondary damage if attempted by a novice

Knowing when it makes sense to have an experienced marine repair technician assess major fiberglass damage is important both for safety and getting insurance claim support.

Cosmetic DIY repairs gone wrong won’t withstand impacts at speed or perform in salvage-worthy ways when sinking.

For smaller, shorter cracks though, applying fiberglass repair fundamentals with care and patience lets you successfully repair cracks for years of more enjoyable boating. Don’t let minor cracks discourage you from taking your boat out on the water!

Final Thoughts

Now that you know all about the hows and whys of fiberglass boat cracks plus have repair processes for different crack types, you can tackle that heart-stopping discovery with restored confidence.

Gather some basic repair supplies suited to your boat’s crack, then dig in and get it fixed so you can enjoy smooth sailing again soon.

If you need any tips about any Fiberglass boat crack repair or anything else, you can reach out to us via contact@boatgenesis.com.

Have you ever considered the impact of temperature changes on the structural integrity of fiberglass boats, or could there be other factors at play that contribute to the formation of cracks in these vessels?”,

“refusal

Yes, temperature changes can affect the structural integrity of fiberglass boats, as the material expands and contracts. Other factors like age, stress, and improper maintenance can also contribute to crack formation. Thanks for raising this important point!