Is your fiberglass boat transom feeling a bit flimsy? Don’t worry, you’re not alone! Many boat owners face this issue at some point. The good news is that reinforcing your transom is totally doable with the right know-how and materials.

In this article, we’ll dive into everything you need to know to get your transom shipshape again.

Why Reinforce Your Transom?

First off, let’s talk about why reinforcing your transom is so important. The transom is that flat surface at the back of your boat where the outboard motor is mounted. It takes a lot of stress and strain from the motor’s weight and vibration.

Over time, this can cause the fiberglass to weaken or even crack.

Reinforcing the transom helps distribute that load and prevent damage. Plus, a solid transom is crucial for safe and efficient boating.

Want to avoid costly fiberglass boat repair mistakes?

Learn how to inspect damage properly, decide when to DIY, and prevent expensive fiberglass problems before they start.

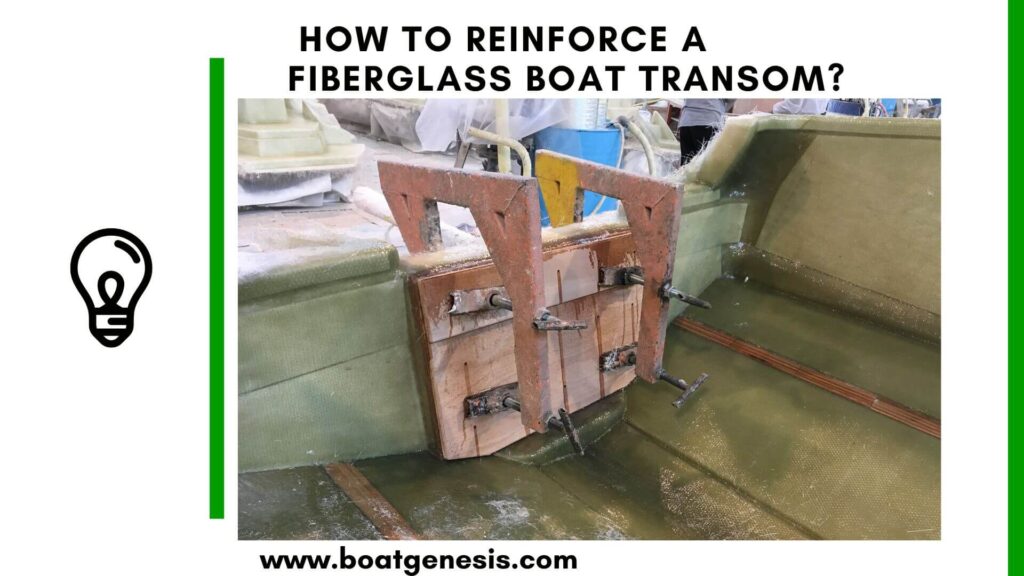

How to Reinforce a Fiberglass Boat Transom?

Here are my recommended steps to reinforce a fiberglass boat transom.

1. Assessing the Damage

Before you start reinforcing, take a close look at your transom’s current condition. Are there any visible cracks or soft spots?

You can check for softness by firmly pressing on the transom from inside the boat. If it feels spongy or gives way, that’s a sign of weakness.

It’s also a good idea to drill a small hole and examine the wood chips for moisture, which can lead to rot.

2. Reinforcement Options

There are a few different ways you can go about reinforcing your transom:

Epoxy and Fiberglass

This is a popular method that involves applying epoxy resin and fiberglass cloth to the transom.

First, thoroughly clean the area and sand it down for better adhesion. Then, apply the epoxy and lay down the fiberglass cloth, smoothing out any air bubbles. You may need multiple layers for added strength.

This guide helps boat owners understand fiberglass damage clearly — what matters, what doesn’t, and when repairs are truly necessary, so small issues don’t turn into expensive mistakes.

See What Every Boat Owner Should Know →Aluminum Plating

Another option is to reinforce the transom with aluminum plates. This provides solid support and helps distribute the load.

You’ll want to use marine-grade aluminum and secure it tightly to the transom with bolts or rivets.

Some folks also add angled aluminum supports tied into the boat’s stringers for extra sturdiness.

Transom Support Bracket

A purpose-built transom support bracket is another route you can take. These are usually made of heavy-duty aluminum and bolt onto the transom to provide additional support.

They’re designed to fit specific boat models, so make sure you get the right one for your vessel.

Tips for a Successful Reinforcement

Whichever method you choose, here are some tips to ensure a strong, long-lasting transom:

- Proper surface prep is key. Make sure the transom is clean, dry, and sanded before starting any reinforcement work.

- If you’re using fiberglass, focus on a smart layup of the cloth rather than just globbing on resin. Too much resin can actually weaken the repair.

- Take your time and allow each layer of epoxy or fiberglass to cure fully before adding the next.

- If you’re not confident in your DIY skills, don’t hesitate to enlist the help of a professional. A botched transom repair can lead to serious problems down the line.

==>> Check out this Fiberglass resin calculator

The Bottom Line

Reinforcing your fiberglass boat transom is an important part of boat maintenance. Whether you opt for an epoxy and fiberglass repair, aluminum plating, or a support bracket, taking action now can save you from costly issues in the future.

With the right approach, you can get your transom solid and ready to handle whatever the water throws your way.

For a closer look at the transom reinforcement process, check out this helpful video from Wildfire Marine. And remember, a little preventative maintenance goes a long way in keeping your boat safe and seaworthy for years to come.

Warren is the founder of BoatGenesis and brings practical experience in fiberglass boat repair, marine equipment testing, and powerboat building. He has worked on a range of repair and restoration projects and now focuses on creating clear, research-based guides to help boat owners avoid costly mistakes and make smarter maintenance decisions. Learn more about Warren.